R&D

By ceaseless reinforcing of technical competitiveness,

ORAZ is consolidating its position as a leading company

in toothbrush industry.

-

Common tufting M/C

daily capacity: 8,000 EA / 8h

Model AP-868 Capacity Max. 850 Tufts/min Power 3.2 kw Dimensions L 1250 x W 1250 x H 1305 mm Function - Good effect to run for continuous 24 hours

- Servo control

- Cam free

- Toothbrush hole position, color monofilament changing and speed can be flexibly adjusted depending on nessarity

- 50 different toothbrush hole arrangement memories

- Convenient operation, easy maintenance

-

Pattern tufting M/C

daily capacity: 6,000 EA / 8h

Model AP-877 Capacity Max. 850 Tufts/min Power 3.2 kw Dimensions L 1250 x W 1250 x H 1305 mm Function - Good effect to run for continuous 24 hours

- All servo control (Including handle changing and color changing)

- 3 color tufting

- Cam free

- Toothbrush hole position, color monofilament changing and speed can be flexibly adjusted depending on nessarity

- 50 different toothbrush hole arrangement memories

-

Automatic tufting & cutting M/C

daily capacity: 8,000 EA / 8h

Model AP-9N48H Capacity Max. 720 Tufts/min Power 2.1 kw Dimensions L 1250 x W 1250 x H 1305 mm Function - Good effect to run for continuous 24 hours

- Servo control - Heat Transfer Unit

- Cam free

- Toothbrush hole position, color monofilament changing and speed can be flexibly adjusted

- 50 different toothbrush hole arrangement memories

- Convenient operation, easy maintenance

-

Manual packaging M/C

daily capacity: 15,000 EA / 8h

Model JY-S7040A Power supply 220V 60Hz Internal air pressure 5~6kg/mm Dimensions W×L×H(1800×1000×1220) Function - Slide type semiautomatic blister packing machine

- Increase worker's safety and efficiency by operating both buttons

- Prevent the worker's accident by installating a light sensor

- Card is not burnt or bent

- Steady and clean adhesion

- No breakdown/failure

-

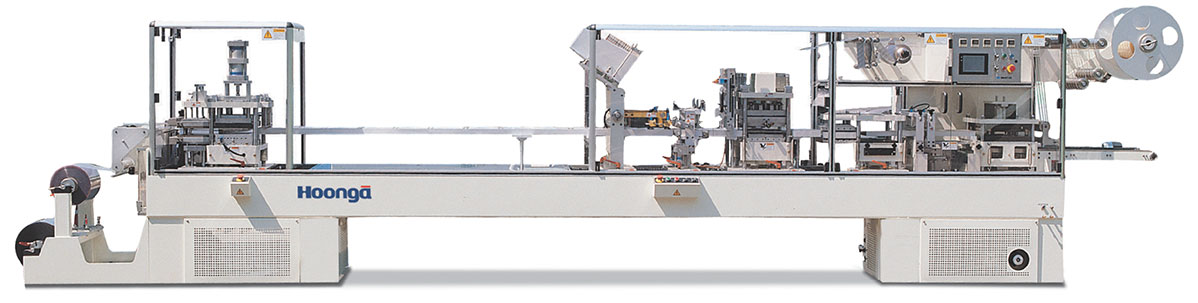

Automatic packaging M/C

daily capacity: 15,000 EA / 8h

Model N8 Function - Up to 20rpm, 160 blisters per minute(In case of Double side blister, Up to 15rpm)

- Flexibility forming material, PET, PET-G, PVC-GAG, etc.

- Form-Fill-Seal-Cut operation on the single bed

- MMI control via PLC & touch panel

- Forming and Sealing station works by Hydraulic cylinder

- Indexing control by servo (N8 +)

- Double punch station for reducing scrap (option)

- High frequency sealing for Double side blister

- Pick & place system for backer card

- Complete safety interlock design

- Double preheating system